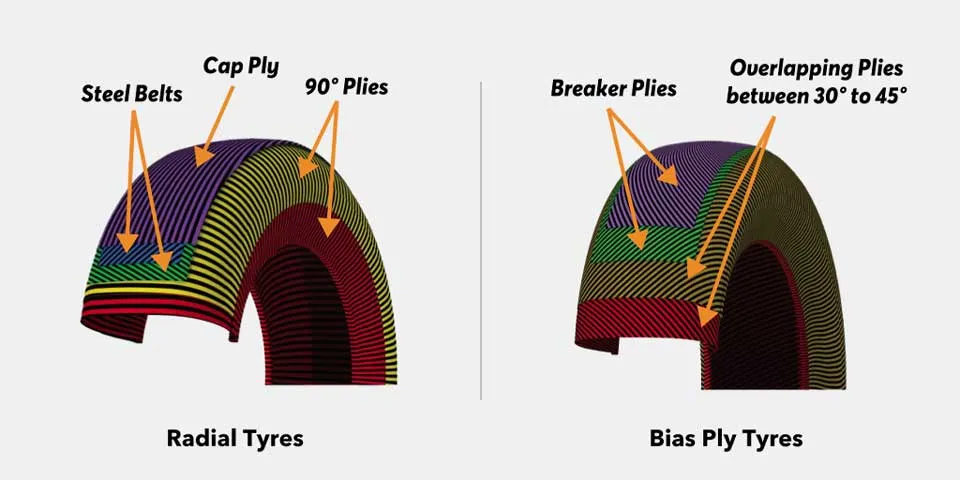

This guide will explain the different structures of these two types of tyres and the pros and cons of each to help you make more informed decisions when choosing your tyres. The internal structure of a tyre can affect every aspect of its performance, such as its traction and wear-resistance. Since Michelin introduced the radial tyre in 1946, it has become the standard type used in new passenger cars, commercial vehicles, and industrial machines due to the increased driving comfort and fuel efficiency it offers. However, you may still find cross ply or “bias ply” tyres on certain classic vehicles, offroad vehicles, tractors and motorcycles.

The cross ply tyre

This type of tyre has been around since 1888. The tyres were invented by John Boyd Dunlop and were first used on a bicycle. The pneumatic design is constructed using a network of interlocking nylon cords, which are layered diagonally across each other at a 45-degree angle to the centre line of the wheel. Along with the tough outer rubber shell, their construction increases the strength and rigidity of the sidewalls. This makes the sidewalls more resistant to wear and tear. This is important for protecting the inner inflated tube which is made from a soft rubber and prevents air loss. If the tube gets punctured, it will result in a flat tyre.

The radial tyre

As mentioned above, radial tyres were introduced over half a century later as a more flexible alternative to their cross ply predecessors. They use steel cords instead of nylon ones, as well as steel belts to support the tread of the tyre. In a radial ply tyre, the cords overlap and are positioned at a 90-degree angle to the wheel’s centre line. The advantage of this design is that the flexibility and strength of the tyre allow it to absorb shocks and impacts more effectively, maintaining contact with the road and generating less heat. Moreover, this construction does not require an inner tube.

If your radial or cross ply tyres are badly punctured or the tread has been worn down, you can easily compare the prices of Michelin tyres and those from other popular brands online. Both types vary in complexity, but it may be possible to repair the tyre using either a sealant or cross ply repair patches, for example.

Radial vs Cross Ply

Cross ply tyres: advantages and disadvantages

- High resistance to sidewall damage

- Cheaper to produce

- Improved vehicle stability in certain driving/working environments

- Lower fuel efficiency

- Reduced driving comfort due to tyre rigidity

- Poor heat dissipation, causing the tyre to wear faster

- A low speed rating, more likely to blow out at high speeds

Radial tyres: advantages and disadvantages

- Improved road contact and vehicle handling

- Improved fuel efficiency

- Improved driving comfort due to flexibility

- A higher speed rating

- Higher resistance to tread wear and less risk of a loss of traction

- The sidewalls are more vulnerable to damage caused by collisions

- Less effective at handling minor bumps in the road due to steel belt

Safety

Under no circumstances should you use tyres with two different constructions on the same axle. It is highly advisable to stick to one type of tyre for both axles for safety reasons related to vehicle stability and weight distribution. In cases where mixing tyres is unavoidable, it is recommended that cross ply tyres are fitted to the front axle and radial ones are fitted at the rear.

Making sure the tyre tread depth complies with safety regulations is also critical. If the tread is too worn, it could cause a loss of traction and result in an accident. This is especially dangerous in wet driving conditions. If you need to replace your tyres quickly and affordably, you can easily select and buy cheap car tyres online.